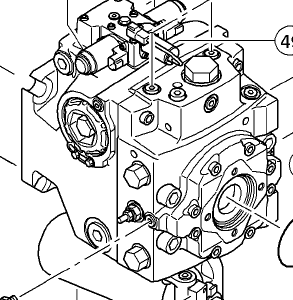

Description

The main difference between a normal wobble box and a heavy-duty wobble box is their capacity to handle the load and power transfer. They are designed to handle higher power and torque loads than normal wobble boxes, making them more durable and better suited for heavy-duty applications.

In practical terms, they may have larger bearings, thicker housing material, and a stronger spindle to handle the increased load. Additionally, heavy-duty wobble boxes may be designed with better sealing and lubrication systems to prevent premature wear and failure.

When choosing a wobble box for a particular application, it’s important to consider the intended use and the amount of power that needs to be transferred. A heavy-duty wobble box may be more expensive than a normal wobble box, but it can provide greater durability and longer service life in heavy-duty applications.

The heavy duty wobble boxes are used on:

| Header Type | Serial Number |

| C750 – C450 Rape Lexion | 437 |

| C900-C300 Rape Lexion/Tucano/Mega/Medion/Dominator | 437 |

| C900-C390 Lexion | 700, 708, 711, 714 |

| C900-C450 Lexion | 715, D02 |

| Flex Head F900, F750, F530-525, F30-20 | 438 |

| Grain Head 18 – 30 | 707 |

| Grain Head G530-525 | 717 |

| Grain Head Vario V535-530 | 718 |

| S900-S40 Soja Lexion | 436 |

| S900-S450 Soja Lexion/Tucano | 440 |

| S900-S450 Soja Mega/Medion/Dominator | 439 |

| V1050 – V540 Vario Lexion/Tucano | 716, D04 |

| V900 – V540 Vario Lexion | 705, 712 |